Snap-on Inc. CEO Nick Pinchuk says his company didn’t lay off any employees during the pandemic — and he reported to work in-person to demonstrate the company’s dedication to the professional-tools manufacturer’s factory employees.

“During Covid, our factories worked every day,” Pinchuk told a Kenosha business audience Friday. “In fact, we had about a third of our white-collar workers work every day and I was one of them. I could not face the factory workers if I wasn’t at my desk.”

Pinchuk, a Vietnam war veteran, said the pandemic presented one of the biggest challenges to the United States since World War II. He said Kenosha-based Snap-on (NYSE: SNA) viewed its role during the pandemic as continuing to supply its professional mechanic customers so they could continue performing their jobs.

Pinchuk, who is 77, has been Snap-on’s president and CEO since 2007 and board chairman since 2009. He joined the company in 2002.

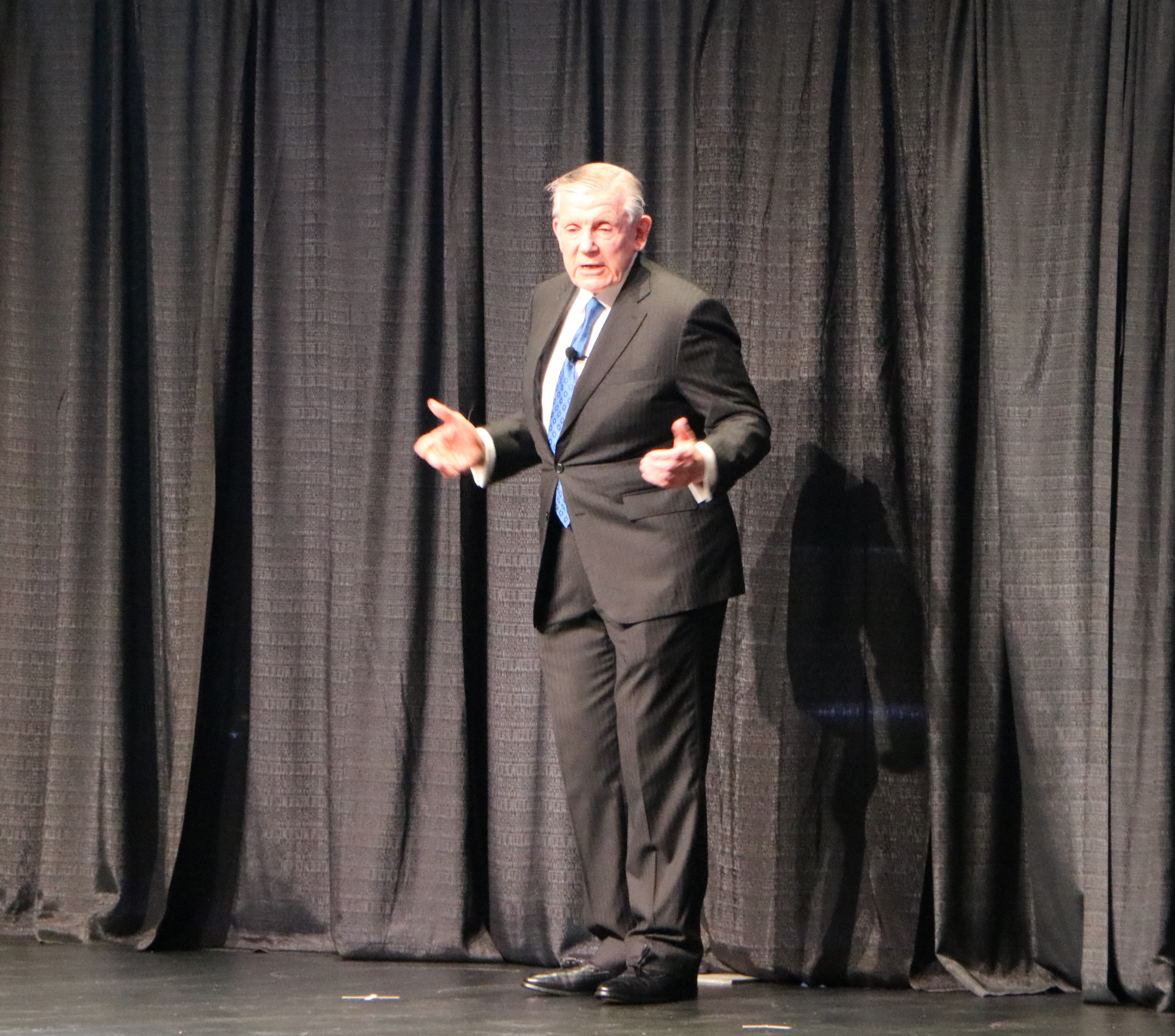

He was the keynote speaker at the Kenosha Area Business Alliance’s half-day “Inspire” event at Journey Church. Pinchuk was at turns self-effacing, humble, humorous and serious in his remarks on leadership that were well-received by an audience of several hundred business and community leaders.

One of Snap-on’s lessons from the pandemic was to adhere to its market strengths, most notably its product and its brand, Pinchuk said. The company also maintained its practice of viewing its employees as people rather than “human capital,” he said.

“We didn’t lay anybody off during Covid because we view them as our most important asset,” said Pinchuk, who said he never contracted the virus.

Snap-on runs plants around the globe including 13 in the United States, one of which is on Milwaukee’s northwest side. Between the corporate headquarters in Kenosha and the Milwaukee plant, Snap-on has 1,050 employees in southeast Wisconsin, according to the latest Milwaukee Business Journal list of largest area private-sector employers.

The plant at 7939 N. Faulkner Road manufactures a large range of sockets, extension bars, pliers, screwdriver blades and bits. Snap-on recently expanded the plant by 26,000 square feet to accommodate growth in its hand-tool business and to expand the company’s product line.

Pinchuk said Snap-on has increased the number of robots in the Milwaukee plant eight-fold over the past decade. He said the company also added to the number of people working there.

“When we talk about our company, we talk about how we can best use our peoples’ time,” he said. “And we array assets — robots or otherwise — around that.”

Read more at the Milwaukee Business Journal.